News & Events

The hydrogen sensor of NanoGrid set a new record

Release time: 2021-09-01

In 2017, NanoGrid Technology began to develop domestic hydrogen sensors under the entrustment of a well-known domestic automobile enterprise. After more than two years of efforts, the company has invented a new process that integrates printing electronic technology and MEMS processing, and developed a new domestic hydrogen sensor with independent intellectual property rights by using non vacuum printing preparation and 1000 ℃ high-temperature sintering process. According to the most authoritative standard "SAE J3089 Character of On Board Vehicular Hydrogen Sensors" for hydrogen sensors at the current vehicle regulation level, the hydrogen sensors produced in batch by the company passed all the rigorous vehicle regulation standard tests and vehicle EMC tests of an automobile group in the first half of 2020.

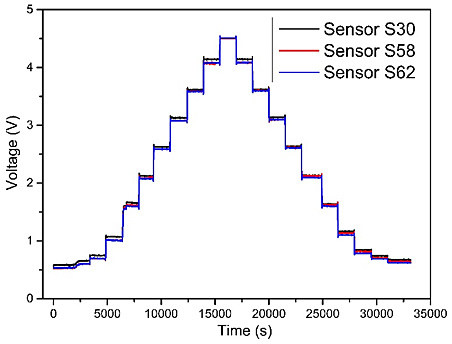

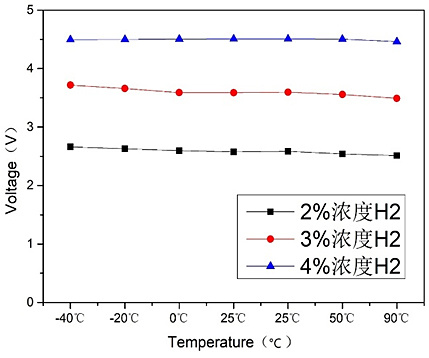

Since 2021, NanoGrid Technology has actively deployed in the hydrogen energy industry and sent its products to many well-known domestic hydrogen supply system and stack system manufacturers for strict testing, including: startup time, response time, display accuracy, environmental adaptability (low temperature, high temperature and humidity, complex gas environment corrosive gas, high concentration pure hydrogen, complex electromagnetic environment, etc.), explosion-proof, life, etc, These indicators all meet or exceed the imported products and are highly praised by the test customers. At present, the company has three types of hydrogen concentration sensors, namely HNC-H2-2 (analog signal), HNC-H2-2C (CAN signal) and HNC-H2-2P (PWM signal). The products have been loaded in batches by many domestic automobile enterprises.

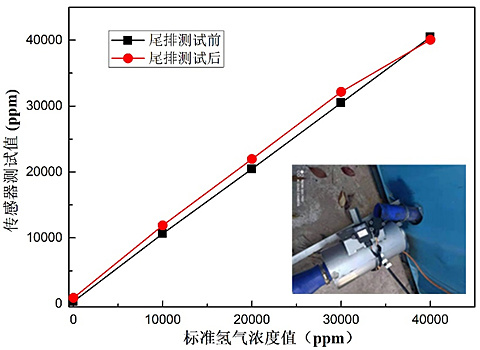

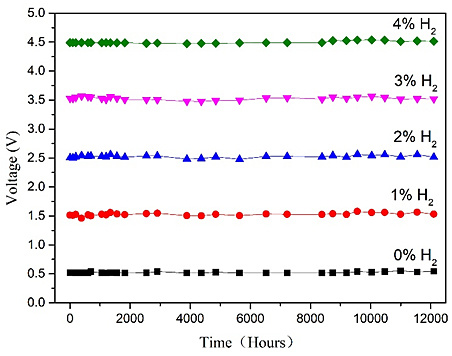

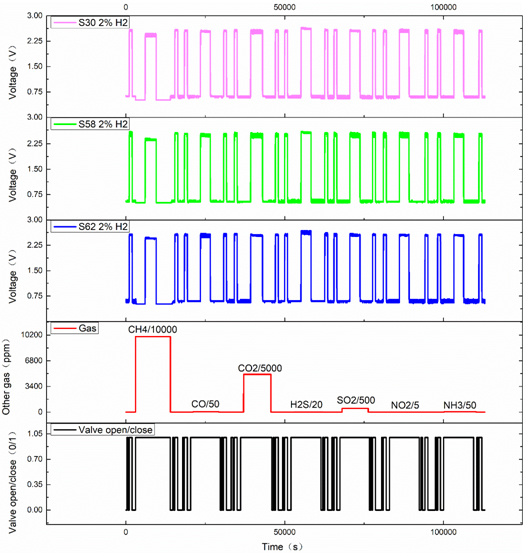

Recently, after the hydrogen sensor of NanoGrid Technology was impacted by high concentration and large flow hydrogen for many times on the test bench of a well-known domestic stack enterprise, the sensor response value did not have any attenuation. More importantly, the product can still be reused after multiple high concentration hydrogen impacts. At present, only NanoGrid Technology's hydrogen sensor products can achieve this performance in the world's known hydrogen sensor products. At the same time, the company's products have experienced more than 1000 hours of tail array test on the tail array test bench of another well-known stack system enterprise, and the response value of the products has no attenuation. Generally, the gas discharged from the stack tail presents a high temperature, high humidity, weak acid environment, which is very harsh. There are few gas sensor products that can pass the stack tail test worldwide. NanoGrid Technology's products can pass the tail test, which is sufficient to demonstrate the high stability and reliability of the products. At the same time, the hydrogen sensor life test of NAG has reached 12100 hours (24 hours of power on, once a week with 1-4% hydrogen concentration for 4 minutes). The output of various performance indicators of the product is stable, and the life test is still ongoing.

Contact: Zhang Kedong 18626164677

Figure 1—Hydrogen concentration sensor (module assembly)

Figure 2—Hydrogen sensor tail exhaust test data

Figure 3—Life test curve of hydrogen sensor

Figure 4—Accuracy test curve of hydrogen sensor

Figure 5—High and low temperature test curve of hydrogen sensor

Figure 6—Hydrogen Sensor Selectivity; Poisoning test curve

Keywords: